The corrugated cardboard production machine consists of units with a length of approximately 150 meters in which various processes are performed. it can be worked from narrow dimensions to 3.3 meters wide widths. The corrugated cardboard machine consists of two units called the wet part and the dry part due to the operations performed. Preheater and shunters.. Temperature is required to condition the paper and perform the adhesion process in the Corrugated Cardboard machine. The most ideal way to provide temperature transmission to the paper is to directly contact the paper with the high conductivity steel rollers.

It is an important material that provides the best protection according to the structure of the product, keeps the product clean and at the same time promotes it, taking into account the storage and transportation characteristics of the product placed in the corrugated cardboard.

Development of Corrugated Cardboard in the World: History, Technological Innovations and Sustainability Corrugated cardboard stands out as an important material in the modern packaging sector. With its lightweight, durable and economical features, corrugated cardboard has created a great revolution in the industrial and commercial fields. In this article, we will examine the historical development of corrugated cardboard, its technological innovations and environmentally friendly features, and examine its development in the world.

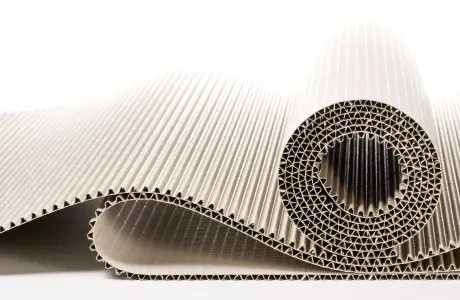

What is Corrugated Cardboard? Corrugated cardboard is a durable packaging material made by placing a wavy (flute) layer between two flat layers of cardboard. This material is widely used in the transportation and packaging industries due to its combination of lightness and durability. The "flute" layer provides resistance to impacts and loads, ensuring safe transportation and storage of products.